TPRC develops Continuous Optical Reflection Characterization (CORC) setup

CORC setup for unidirectional (UD) tapes has been developed as part of the composites manufacturing project in the NXTGEN High-tech program

Posted On 07 Apr 2025

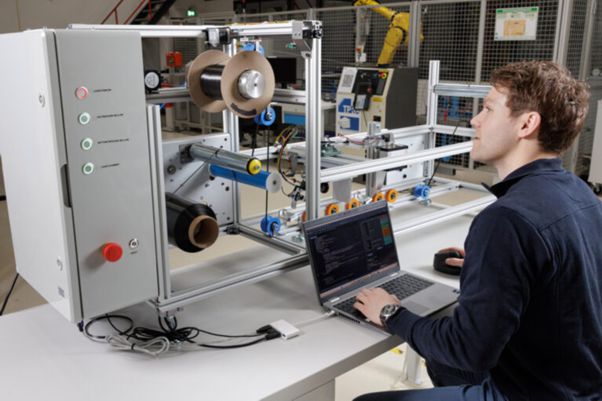

Developer of the CORC setup (Joran Geschiere) working with the machine.

A Continuous Optical Reflection Characterization (CORC) setup for unidirectional (UD) tapes has been developed by TPRC (Netherland) as part of the composites manufacturing project in the NXTGEN High-tech program.

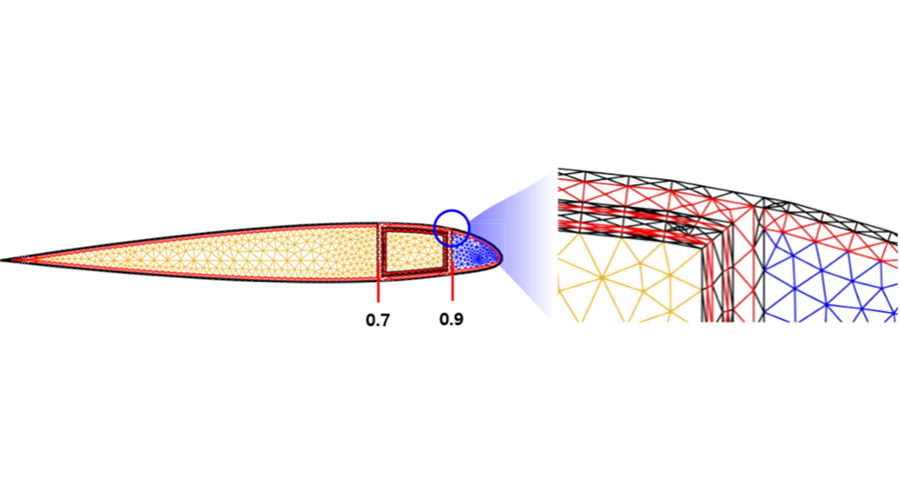

The goal was to develop a setup that can characterize entire spool lengths of UD tape meant for the automatic fiber placement (AFP) process. The material properties of interest are far from conventional. The setup measures the way in which the tape surface scatters laser light in so-called ‘reflection-patterns’. It can do so while varying the angle of the laser with respect to the surface and with respect to the fiber orientation of the tape. The setup can operate autonomously while generating large quantities of data, replacing labor-intensive manual characterization experiments.

The laser reflection patterns can be used to fit bi-directional reflection distribution (BRDF) functions specific to any (batch of) material. These fitted functions can serve as an input for optical simulations of the AFP process. This can enhance the accuracy predicted nip-point temperatures obtained with AFP process simulations.

Besides simulation accuracy, the data can also be used by material manufacturers during the development of new materials particularly suited for the AFP process. Different optical behavior between batches can quickly be distinguished without the need for extensive AFP test campaigns.

Next to the laser scattering measurement, a commercially available laser line scanner is installed in the CORC-setup. With this, we can map the topography of the tape surface up to microscale accuracy to provide additional data about the tape material and to study the underlaying mechanisms causing the differences in optical behavior.

The setup can wind the tape material tightly on a new spool after testing, this allows for use of the spool in the AFP process after acquiring the data.

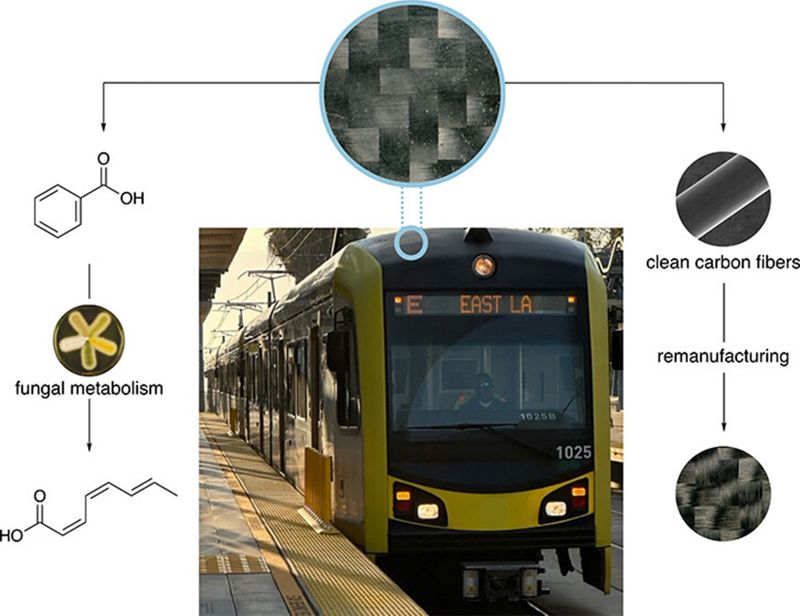

About NXTGEN

Composites manufacturing is one of the topics that NXTGEN Hightech addresses in the next seven years to create the new generation of sustainable high-tech equipment. In this scope, the aim is to develop compact, flexible and robotized production lines for processing lightweight composite structures. An important focus aspect in this is recycling of thermoplastic composites. The project is supported by Nationaal Groeifonds.

Realted Content

Siemens unveils breakthrough innovations in ind ...

Siemens showcased its vision for the ...

Read More