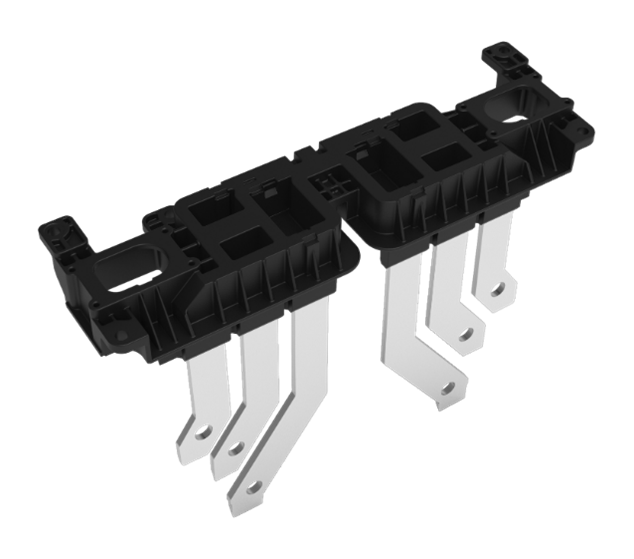

RWC delivers first ultra-high-performance frac plugs for new contract

Rock West Composites has developed a composite material for frac plugs that can withstand cyclical testing at 12,000 psi and 250°F without failure

Posted On 01 May 2025

Rock West Composites (RWC) begins delivery of new ultra-high-performance frac plug billets to an oilfield service company that is a major supplier to the hydraulic fracturing market. RWC has developed a composite material for frac plugs that can withstand cyclical testing at 12,000 psi and 250°F without failure.

This new ultra-high-performance frac plug material has been in development for over a year. It is made of filament wound fiberglass composite with a custom epoxy resin. The plugs have passed rigorous testing in RWC’s laboratory and the customer’s in-situ downhole environments. Each lot is proof tested to guarantee performance for these extreme applications.

RWC manufactures and tests the plug billets at its facility in West Jordan, Utah, the location of its filament winding center of excellence. This facility has 27 spindles across multiple winders and the capacity to manufacture up to 6,000 billet tubes per month. RWC anticipates significant market demand for this product due to the increasing challenges oilfield service companies face with downhole operations.

“We brought our filament winding expertise to the table. Our engineering team works on highly demanding applications, including space and aerospace, so we took that knowledge of material performance downhole,” said Adam Creer, Commercial Segment Director. “We are glad to have partnered with our customer to meet their very demanding requirements and develop our own technology that solves an industry-wide challenge.”

Realted Content

BASF launches innovative PPA for electric vehic ...

BASF announced that its newly develop ...

Read More