NTTM and System 5S develop firefighting suit using aluminised coated glass fabrics

The specialized fire fighter suits are used by Firefighting & Emergency services, Defence forces, Oil & Gas industry, Aerospace & Aviation, Power Plants & Thermal Industry, etc.

Posted On 18 Apr 2025

The National Technical Textile Mission (NTTM), an initiative by the Ministry of Textiles, Government of India, has supported an innovative project titled “Development of Specialized Firefighting Suit.” These specialized fire fighter suits are used by Firefighting & Emergency services, Defence forces, Oil & Gas industry, Aerospace & Aviation, Power Plants & Thermal Industry, etc. Manufacturing of firefighting suits in India is in its nascent stage and currently, in India, specialized firefighting suits (also known as fire entry suits) are imported mostly from Europe, the USA, and China. The NTTM project is implemented by Northern India Textile Research Association (NITRA), in collaboration with its industrial partner, M/s System 5S Private Ltd.

The annual current consumption would be approximately 1000 sets by various End Users in India. However, with the introduction of an Indian Certified Aluminized suit, the consumption could go up exponentially. M/s SYSTEM 5S Pvt. Ltd has an annual production capacity of 1000 suits with this commercialisation.

According to EN 1486 (a European Standard that specifies the requirements and test methods for protective clothing for fire fighters), protective clothing for specialized firefighting must protect the full body, including the head, hands, and feet, against radiant heat and flame impingement. This protective gear includes a garment, a hood (integrated or separate), gloves, and over boots. Additionally, the design of such suits is intended for use with respiratory protection, with designs varying on whether the breathing apparatus is worn inside or outside the protective clothing.

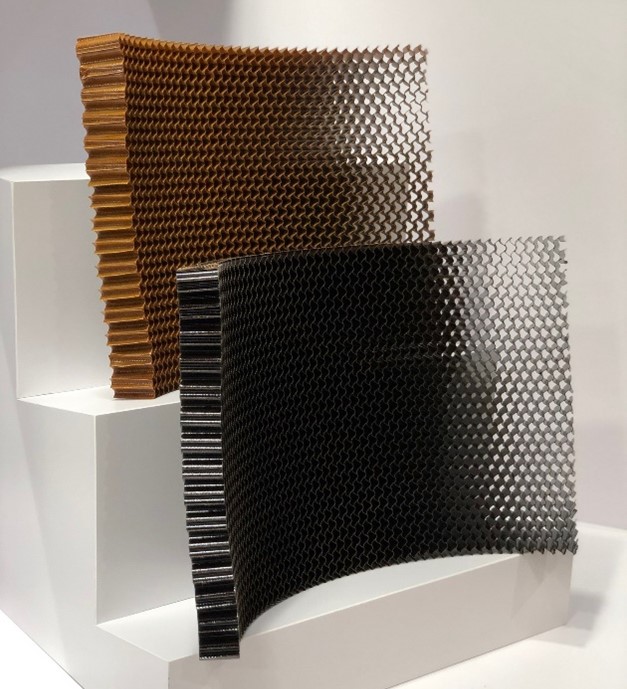

M/s System 5S Private Ltd, has developed an indigenous Specialized Fire Fighting Suit, designed to meet the EN 1486 or ISO 15538 standards. The development process prioritised the safety, comfort, and ease of donning and doffing for fire fighters. The suit is developed using aluminised coated glass fabrics, OPAN (Oxidized Polyacrylonitrile) Nonwoven battings and FR (Flame Resistant) viscose fabric. All the inner layers are quilted together. The industrial partner has already begun manufacturing these suits for trial purposes, and commercial manufacturing will commence once the fire manikin test is completed successfully, as per the EN ISO 13506 (a standard that defines a test method for evaluating the performance of protective clothing against heat and flame) standard, to ensure the suit meets all necessary performance requirements.

Realted Content

BASF launches innovative PPA for electric vehic ...

BASF announced that its newly develop ...

Read More