Cathay bio-based composites aviation temperature-controlled containers obtain approval

The RAP-AT1 active aviation temperature-controlled container of Qingdao Honghu Aviation Technology Co., Ltd., a subsidiary of Haier BioMedical, passed the airworthiness review of the Civil Aviation Administration of China

Posted On 21 Mar 2025

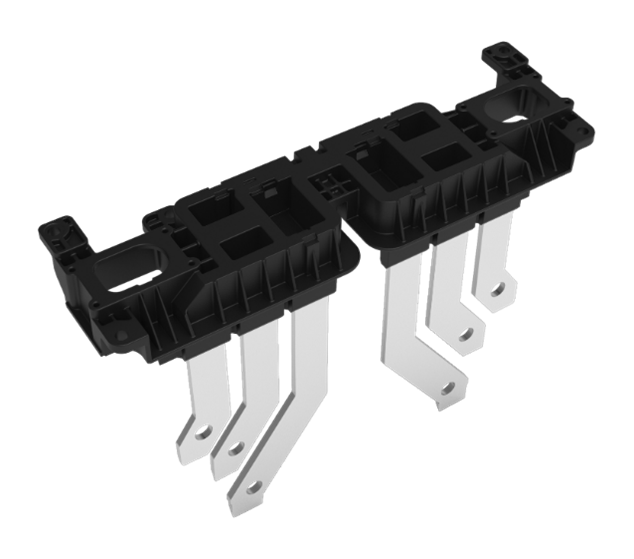

The RAP-AT1 active aviation temperature-controlled container of Qingdao Honghu Aviation Technology Co., Ltd., a subsidiary of Haier BioMedical, passed the airworthiness review of the Civil Aviation Administration of China, obtained the Technical Standard Regulations Project Approval (CTSOA), and officially entered the commercial stage. This achievement is not only a major technological breakthrough in the field of aviation cold chain equipment in China, but also a landmark achievement in the implementation of the "14th Five-Year Plan for Aviation Logistics Development" in the research and development of modern professional transportation equipment.

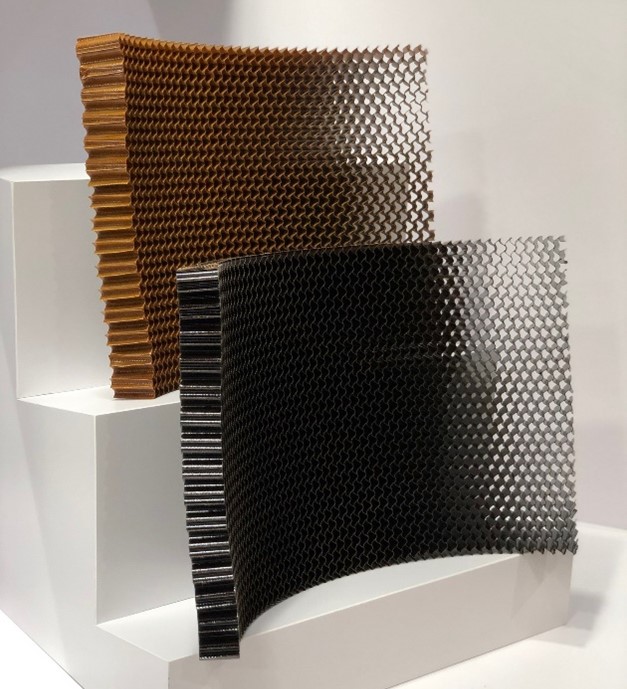

As one of the core suppliers of Qingdao Honghu's active aviation temperature-controlled containers, Cathay Biotech provides it with low-carbon, high-performance continuous fiber reinforced thermoplastic bio-based polyamide composite materials, which helps RAP-AT1 perform well in terms of lightweight, thermal insulation, and strength. It can effectively reduce the energy consumption and carbon emissions of air transportation under the premise of efficient thermal insulation, high strength and wear resistance, and provide strong support for the green and sustainable development of aviation cold chain. At the certificate awarding ceremony, Cathay Biotech received a letter of thanks from Qingdao Honghu.

Cathay Bio-based composite materials are a new type of high-performance bio-based thermoplastic composite materials. The matrix resin can be made of different types of bio-based polyamides such as low-temperature long-chain, medium-temperature and high-temperature. Based on excellent melt fluidity, it can be composited with high proportions of continuous glass fiber/carbon fiber. The strength/modulus can replace metal, and the density is only 1/4 of steel and 2/3 of aluminum. It also has lower carbon emissions and has broad application prospects in new energy, construction, transportation and logistics. It is expected to achieve "plastic instead of steel, plastic instead of aluminum, thermoplastic instead of thermosetting materials" in large-scale structural parts. While providing cost-effective products, it also brings green and low-carbon technology solutions to traditional industries.

The successful application of bio-based composite materials in aviation temperature-controlled containers provides a material foundation for technology upgrades and product innovations for the development of the aviation cold chain industry. In the future, Cathay Bio will continue to work closely with partners in various fields to provide low-carbon, high-performance green and sustainable solutions, and jointly promote more downstream fields to complete their own industrial innovation and development.

Realted Content

BASF launches innovative PPA for electric vehic ...

BASF announced that its newly develop ...

Read More